Time translates directly into cost in high-volume logistics environments. Whether managing hundreds of trailer movements each day at a distribution hub or coordinating inbound deliveries at a manufacturing facility, logistics teams rely heavily on precise and timely trailer identification.

Delays at entry points, incorrect trailer assignments, and incomplete records can trigger a chain reaction of operational issues, including detention charges, compliance complications, and missed delivery windows.

Truck Trailer Recognition provides a reliable solution to these challenges. This technology automates the capture and logging of trailer identifiers, helping to reduce manual effort, minimize errors, and improve visibility across yard operations. With accurate trailer data available in real time, logistics teams gain better control over workflows, increase gate throughput, and strengthen documentation for audits or regulatory checks.

This guide introduces the principles behind Truck Trailer Recognition and Truck Number Identification and explains how they function in practice, providing a practical overview of their benefits and implementation.

Truck Trailer Recognition Systems Supports Yard Efficiency

Truck Trailer Recognition refers to the use of computer vision and OCR (Optical Character Recognition) to automatically detect and capture trailer IDs as trucks enter or move through a logistics facility. These trailer numbers—typically printed on the side or rear—are read in real time using strategically placed cameras. OCR extracts the alphanumeric ID from the image of the truck captured by cameras, while artificial intelligence (AI) enhances accuracy even in poor lighting conditions, adverse weather, or angled views.

Once captured, the trailer number is time-stamped and transmitted into systems such as a Yard Management System (YMS) or Transportation Management System (TMS). This removes the need for manual entry and ensures that trailer data is both immediate and reliable across all operational systems.

This process enables effective truck number identification. When trailer numbers are automatically read and recorded using OCR and AI, Truck Trailer Recognition ensures each trailer is correctly identified as it enters, moves through, or exits the yard. Logistics systems can then track trailer activity in real time, verifying appointments, updating shipment statuses, and confirming trailer positions. With this level of automation and visibility, facilities can prevent misplaced trailers, missed dock assignments, and shipment delays that often result in operational disruptions and audit issues.

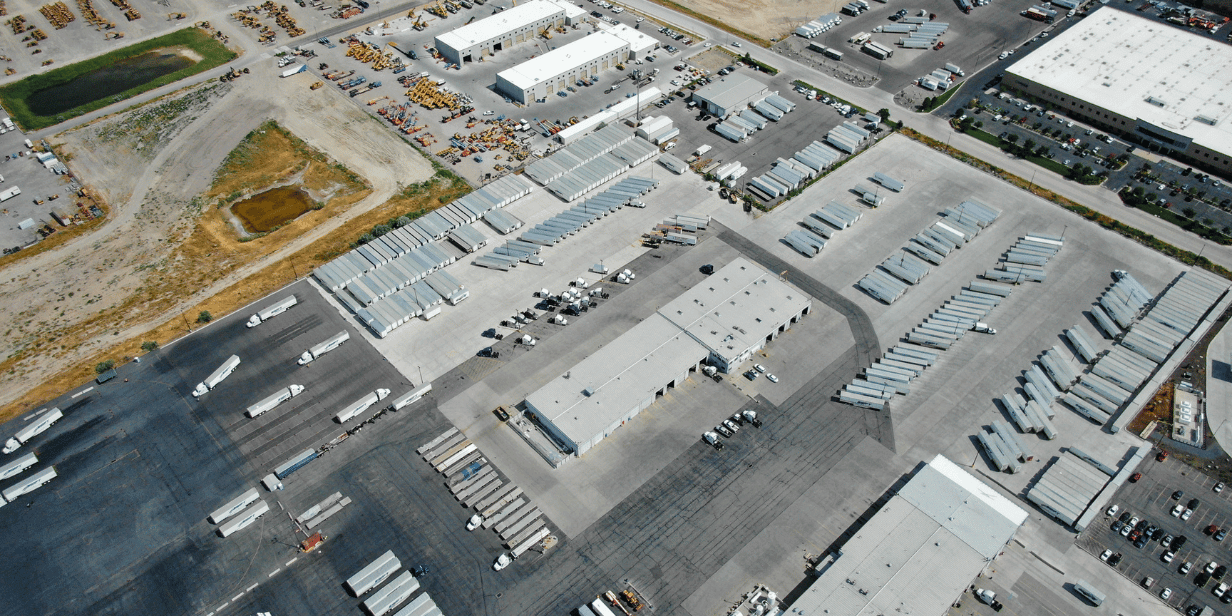

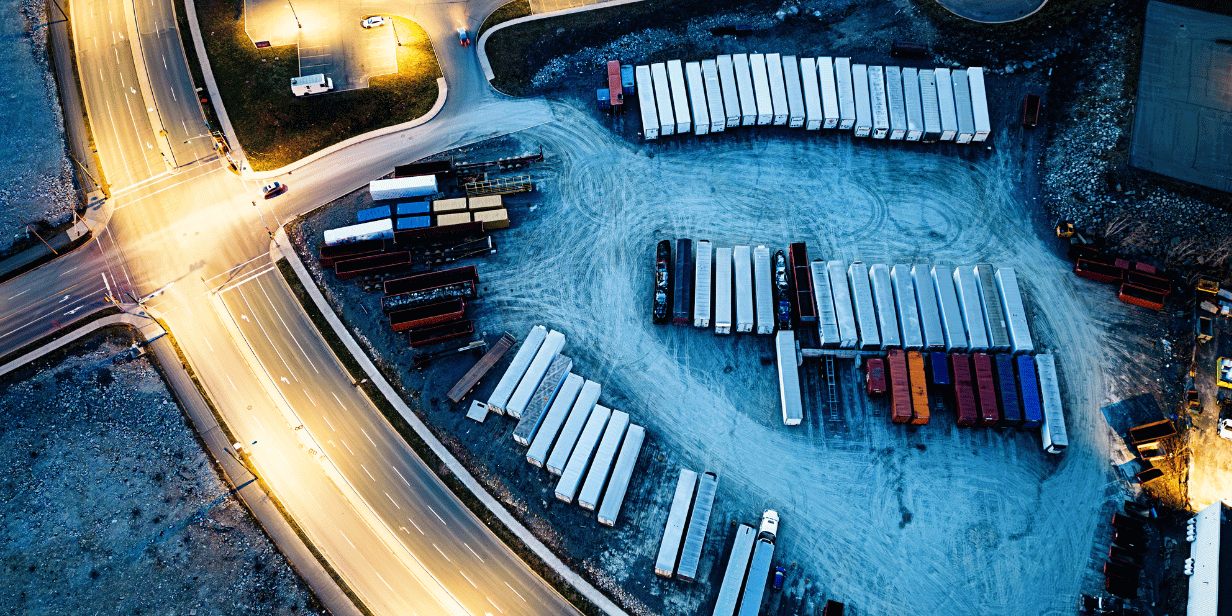

Vast Yard with Several Trucks. Source: Canva

Real-World Benefits of Truck Trailer Recognition for Yard Operations

Truck Trailer Recognition delivers measurable improvements across core yard operations by eliminating manual data entry and enhancing trailer visibility from entry to exit. With cameras automatically capturing trailer IDs, logistics teams gain accurate, time-stamped data without slowing down the flow of vehicles.

One of the most immediate benefits is the reduction in gate dwell time. Automated identification speeds up trailer check-in and check-out by removing the need for manual logging, badge scanning, or handwritten forms. This allows more trucks to move through the gate in less time, something that’s critical for high-volume yards or facilities with tight delivery schedules.

Using a Truck Trailer Recognition system also supports better yard visibility. Each trailer’s movement is tracked in real time and synced with Yard Management Systems (YMS) or Transportation Management Systems (TMS). This helps eliminate misplaced trailers, ensures trailers are staged correctly, and minimizes the time spent searching for equipment.

With accurate trailer data available immediately, logistics teams can optimize dock assignments and reduce turnaround times. Instead of relying on radio calls or clipboards, dispatchers and yard managers can make informed decisions using up-to-date information.

Replacing manual processes also allows facilities to lessen data entry errors and paperwork bottlenecks. Trailer movements are logged digitally, reducing discrepancies in reporting and improving audit readiness.

Lastly, having a system that automatically does truck number identification frees up yard personnel to focus on higher-value tasks. Instead of monitoring clipboards or manually checking trailer IDs, staff can concentrate on managing trailer movements and maintaining throughput.

For facilities handling hundreds of trailer movements each day, these operational improvements add up to significant gains in efficiency, accuracy, and cost control.

Boxes inside a truck trailer. Source: Canva

Implementation Best Practices for Truck Trailer Recognition

Transitioning from manual trailer logging to an automated Truck Trailer Recognition solution requires careful planning, but following a structured rollout ensures reliable performance and rapid ROI.

1. Conduct a Thorough Site Assessment

Begin with a walk-through of gate lanes, yard traffic patterns, and lighting conditions. Note vehicle speed, stopping points, and any obstructions that could interfere with a clear camera view of trailer numbers.

Truck driving on the road at night with lights on. Source: Canva

2. Select the Right Cameras and Mounting Positions

High-resolution IP cameras (2–4 MP) with global shutters capture crisp images of moving trailers. Mount cameras 3–4 meters above ground, angled toward the trailer’s rear or side to maintain at least 100 pixels across the trailer ID. Add LED or infrared illumination at night to maintain consistent image quality.

Read: Best ANPR Camera System Setup

3. Plan Systems Integration Early

Ensure the recognition engine can transmit data to your Yard Management System (YMS), Transportation Management System (TMS), or warehouse software using secure APIs or webhooks. Confirm that time-stamps, trailer IDs, and confidence scores map correctly to existing data fields.

4. Launch a Controlled Pilot

Start with a single gate or lane. Run the system for 30–45 days to benchmark accuracy, gate dwell times, and trailer match rates. Compare new data against historical metrics to validate improvements before scaling to additional lanes.

5. Train Staff and Update Standard Operating Procedures

Provide concise training for gate guards, yard drivers, and dispatchers on how to view recognition results and resolve exceptions. Update SOPs to reflect the new automated check-in/check-out process and outline escalation steps for unreadable plates.

6. Monitor KPIs and Maintain the System

Track key performance indicators such as capture rate, false-read percentage, and average gate cycle time. Schedule periodic accuracy audits, clean camera lenses, and apply software updates from the vendor to keep the system operating at peak performance.

Power of ALPR + TruckID

Integrating Automatic License Plate Recognition (ALPR) with Truck Trailer Recognition enhances both security and operational efficiency. Matching the trailer ID captured through TruckID with the tractor unit’s license plate ensures that the correct vehicle is hauling the correct load. This verification step helps prevent unauthorized swaps, cargo theft, and tampering incidents.

At the gate, ALPR cameras capture the tractor’s license plate while TruckID reads the trailer number simultaneously. The system cross-checks both identifiers against approved records stored in the Yard Management System (YMS) or the Transportation Management System (TMS). When the match is confirmed, the gate opens automatically, allowing authorized entry into the logistics facility. This automated verification not only strengthens perimeter security but also speeds up throughput, eliminating delays caused by manual checks.

Following these best practices helps ensure that Truck Trailer Recognition delivers consistent, high-accuracy data, smoother gate operations, and measurable efficiency gains across the yard.

Trucks lined up and parked. Source: Canva

Key Factors for Choosing a Truck Trailer Recognition System

Selecting a Truck Trailer Recognition solution requires more than mounting cameras. The platform must align with your facility’s layout, IT architecture, and long-term growth plans. The criteria below highlight capabilities found in leading solutions—attributes that closely match the approach used by industry-proven vendors.

Camera Resolution and Positioning

Look for ALPR systems that recommend 2–4 MP global-shutter cameras and provide camera-placement guidelines or built-in “pixel-per-ID” calculators. Clear specifications help you achieve reliable reads in low light, harsh weather, or angled views.

Accuracy in Challenging Conditions

Top ANPR solutions train their OCR models on millions of trailer images from diverse regions and conditions, then automatically push weekly model updates. Consistent improvements maintain high accuracy even when trailer numbers are faded, dirty, or partially obscured.

System Integration

A single REST API that supports both cloud and edge deployments simplifies connection to Yard Management Systems (YMS), Transportation Management Systems (TMS), or warehouse software. SDKs in Python, C#, and other languages, plus webhook callbacks, shorten development cycles.

Aerial vie of trailers inside a truck yard. Source: Canva

Deployment Flexibility

The strongest platforms allow cloud processing, on-prem appliances, or a hybrid of both, using the same API and licensing model. This flexibility supports low-latency gates, remote yards with limited bandwidth, and enterprise-wide roll-outs under one subscription.

Security, Privacy, and Compliance

Look for TLS 1.2+ encryption, ISO-certified data centers, and options to store images locally for GDPR or CTPAT compliance. Role-based access controls ensure only authorized staff can view plate imagery or trailer logs.

Support, Analytics, and Maintenance

Vendors offering 24/5 engineer support, camera-tuning guides, and health dashboards help keep accuracy above 95 %. Built-in analytics—including capture rate, gate dwell time, and exception logs—provide proof of ROI without third-party tools.

Scalability and Future-Proofing

Pay-as-you-grow licensing and the ability to add new lanes or sites through simple API provisioning future-proof the investment. Edge processing on low-power hardware ensures expansion is not constrained by server costs.

Total Cost of Ownership

Factor in camera pricing, lightweight edge hardware, per-scan or per-site licensing, and included software updates. Transparent pricing and a no-contract trial—often with several thousand free recognitions—help validate value before full deployment.

Vendor Track Record and References

Seek published case studies or verifiable accuracy benchmarks from yards with similar volume and environmental challenges. A provider with thousands of active sites worldwide and deployments in multiple climates demonstrates real-world reliability.

Selecting a Truck Trailer Recognition platform that meets these criteria positions your yard for smooth implementation, sustained accuracy, and measurable efficiency gains, without locking you into rigid hardware or costly re-integration down the line.

Use Cases: Where Truck Trailer Recognition Brings the Most Value

The benefits of Truck Trailer Recognition are most apparent in environments where trailer volume is high, manual logging creates delays, and accurate records are essential for operations. Facilities that depend on timely check-ins and precise tracking stand to gain the most from implementing automated trailer identification.

Here are some of the key settings where this technology delivers strong returns:

Distribution and Fulfillment Centers

These sites manage constant trailer movement, with inbound shipments arriving throughout the day and outbound trailers departing on tight schedules. Automating Truck Number Identification speeds up gate operations, reduces detention charges, and improves trailer turnover. Real-time updates to Yard Management Systems support tighter coordination between gate check-ins and dock assignments.

Ports and Intermodal Yards

At maritime ports and rail hubs, trailer numbers must be matched quickly to containers, bookings, or customs documents. Manual tracking is often unreliable due to scale, pace, and environmental factors. Truck Trailer Recognition helps maintain visibility as trailers enter or exit the yard and ensures accurate data is shared with port authorities and logistics partners.

Manufacturing Plants

Facilities that receive raw materials and ship finished goods often operate on lean inventory models. Knowing exactly which trailers have arrived, where they are located, and whether they’re on schedule helps keep production moving. Automated trailer ID capture supports just-in-time delivery models and helps prevent line stoppages caused by misrouted or delayed trailers.

Logistics Parks and 3PL-Managed Facilities

Third-party logistics (3PL) providers handle multiple clients across large yards or warehouse networks. Each trailer movement needs to be tracked for billing, compliance, and load management. A reliable recognition system helps maintain service-level agreements, supports traceability, and improves customer reporting without placing extra load on staff.

Across all of these settings, Truck Trailer Recognition improves data consistency, speeds up routine workflows, and strengthens operational control. The common thread is the need to manage trailer movement efficiently—whether for speed, visibility, or compliance.

License Plates from France. Source: ANPR for France

Truck Trailer Recognition: Next Steps

Efficient trailer flow is critical in high-volume logistics operations. Manual logging not only slows gate throughput but also introduces errors that obscure yard visibility and inflate detention costs. Truck Trailer Recognition remedies these challenges with a scalable, automated approach that captures trailer numbers quickly and accurately.

This guide has shown how computer vision and OCR transform trailer identification, from camera placement and system integration to real-time data delivery. The technology adapts readily to a variety of facilities, including distribution centers, ports, manufacturing plants, and 3PL hubs, providing a single source of truth for trailer movements.

Organizations facing recurring trailer delays, mounting detention fees, or audit inconsistencies should evaluate automated recognition as the next step in yard modernization. Platforms such as Plate Recognizer’s TrailerID integrate with existing YMS or TMS environments and support both cloud and on-premise deployments, reducing the need for disruptive infrastructure changes.

To see how it can work in your facility, start a free trial of Plate Recognizer’s TrailerID. You’ll be able to evaluate performance, accuracy, and integration firsthand and determine whether this technology is the right fit for your yard operations.